Pressix CC 41 - Assembly System

Channel MS 41 - Technical Data

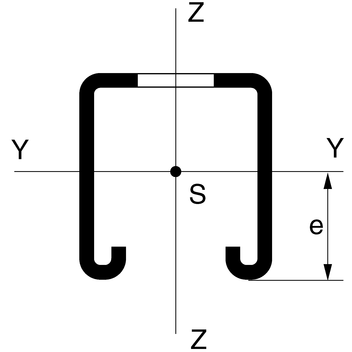

| Type W/H/Th [mm] | Section modulus [cm3 ] | Moment of inertia [cm4 ] | Radius of gyration [cm] |

|---|---|---|---|

| 41/21/1,5 | Wy : 0.70 Wz : 1.71 | ly : 0.78 lz : 3.50 | iy : 0.78 iz : 1.65 |

| 41/21/2,0 | Wy : 0.82 Wz : 2.11 | ly : 0.92 lz : 4.32 | iy : 0.75 iz : 1.64 |

| 41/31/2.0 | Wy : 1.61 Wz : 2.90 | ly : 2.55 lz : 5.96 | iy : 1.10 iz : 1.69 |

| 41/41/2.0 | Wy : 2.50 Wz : 3.65 | ly : 5.21 lz : 7.48 | iy : 1.44 iz : 1.73 |

| 41/41/2.5 | Wy : 2.94 Wz : 4.39 | ly : 6.17 lz : 9.01 | iy : 1.44 iz : 1.73 |

| 41/45/2.5 | Wy : 3.42 Wz : 4.76 | ly : 7.85 lz : 9.75 | iy : 1.55 iz : 1.73 |

| 41/52/2.5 | Wy : 4.32 Wz : 5.39 | ly : 11.43 lz : 11.05 | iy : 1.78 iz : 1.75 |

| 41/62/2.5 | Wy : 5.75 Wz : 6.29 | ly : 18.08 lz : 12.91 | iy : 2.10 iz : 1.77 |

| 41-75/65/3.0 | Wy : 8.13 Wz : 10.27 | ly : 30.67 lz : 38.51 | iy : 2.25 iz : 2.52 |

| 41-75/75/3.0 | Wy : 10.29 Wz : 11.41 | ly : 44.30 lz : 42.80 | iy : 2.53 iz : 2.48 |

| 41/21/2.0 D | Wy : 2.35 Wz : 4.22 | ly : 4.94 lz : 8.65 | iy : 1.24 iz : 1.64 |

| 41/41/2.0 D | Wy : 7.49 Wz : 7.30 | ly : 30.73 lz : 14.97 | iy : 2.48 iz : 1.73 |

| 41/41/2.5 D | Wy : 8.96 Wz : 8.79 | ly : 36.73 lz : 18.03 | iy : 2.46 iz : 1.72 |

| 41/45/2.5 D | Wy : 10.48 Wz : 9.52 | ly : 47.18 lz : 19.51 | iy : 2.70 iz : 1.73 |

| 41/52/2.5 D | Wy : 13.41 Wz : 10.78 | ly : 69.75 lz : 22.11 | iy : 3.11 iz : 1.75 |

| 41/62/2.5 D | Wy : 18.16 Wz : 12.59 | ly : 112.63 lz : 25.82 | iy : 3.71 iz : 1.77 |

| 41-75/65/3.0 D | Wy : 23.24 Wz : 20.54 | ly : 151.10 lz : 77.02 | iy : 3.53 iz : 2.52 |

| 41-75/75/3.0 D | Wy : 30.66 Wz : 22.83 | ly : 230.02 lz : 85.60 | iy : 4.07 iz : 2.48 |

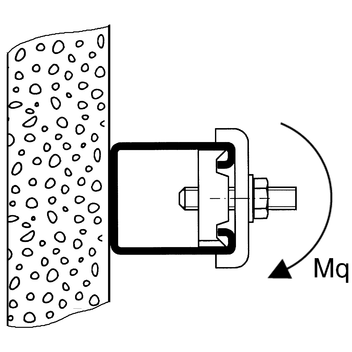

| Type W/H/Th [mm] | Cross section A [cm2 ] | Distance e [cm] | Max. point carrying moment Fmax (tension) [kN] | Max. torsional moment Mq [Nm] |

|---|---|---|---|---|

| 41/21/1.5 | 1.27 | 1.11 | 2.0 | 44.5 |

| 41/21/2.0 | 1.60 | 1.11 | 4.0 | 44.5 |

| 41/31/2.0 | 2.08 | 1.58 | 4.0 | 44.5 |

| 41/41/2.0 | 2.48 | 2.07 | 4.0 | 44.5 |

| 41/41/2.5 | 3.03 | 2.09 | 6.0 | 44.5 |

| 41/45/2.5 | 3.23 | 2.29 | 6.0 | 44.5 |

| 41/52/2.5 | 3.58 | 2.64 | 6.0 | 44.5 |

| 41/62/2.5 | 4.08 | 3.14 | 6.0 | 44.5 |

| 41-75/65/3.0 | 6.03 | 3.77 | 10.0 | 44.5 |

| 41-75/75/3.0 | 6.92 | 4.30 | 10.0 | 44.5 |

| 41/21/2.0 D | 3.20 | 2.10 | 4.0* | 44.5 |

| 41/41/2.0 D | 4.96 | 4.10 | 4.0* | 44.5 |

| 41/41/2.5 D | 6.06 | 4.10 | 6.0* | 44.5 |

| 41/45/2.5 D | 6.46 | 4.50 | 6.0* | 44.5 |

| 41/52/2.5 D | 7.16 | 5.20 | 6.0* | 44.5 |

| 41/62/2.5 D | 8.16 | 6.20 | 6.0* | 44.5 |

| 41-75/65/3.0 D | 12.06 | 6.50 | 10.0* | 44,5 |

| 41-75/75/3.0 D | 13.84 | 7.50 | 10.0* | 44,5 |

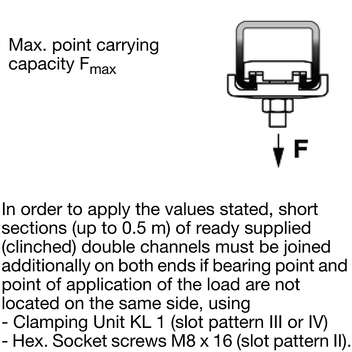

D = Double channel

| * | Double channels with max. length up to 0,5 m should be connected at both ends, if bearing and point of load incidence are not on the same side: Slot pattern 2: with Hexagon socket screw M8 x 16 Slot pattern 3 or 4: by means of Clamping Unit KL 1. |

All values in both tables refer to slotted channels.