Product catalogue

19 out of 115 results

Filters

19 out of 115 results

Speed Nut NT CC41

5 Variants

In particular useful when installing in vertical channels or in places of difficult access. Further advantages: for all Sikla Channels MS 41, independent of the height of the channel, no getting stuck on bolt heads when sliding in the channel, no appearance of settlement after tightening.

Speed Nut NT CC41 A4

1 Variant

In particular useful for installation in vertical channels or where access is difficult. Further advantages: Can be used in all stainless steel Sikla Channels of 27mm width, independent of the channel's height. No getting stuck on bolt heads when sliding in the channel. No appearance of settlement after tightening.

Speed Nut NT CC41 HCP

4 Variants

In particular useful for installation in vertical channels or where access is difficult. Further advantages: Can be used in all Sikla Channels of 27mm width, independent of the channel's height. No getting stuck on bolt heads when sliding in the channel. No appearance of settlement after tightening. The HCP coating meets special corrosion protection requirements.

Support Bracket WK 100-150 HCP

1 Variant

Sikla Support Brackets may be used for wall, floor and overhead pipe installations. Depending on the site, pipes may lie on the support bracket (U-bolt), be arranged in vertical position or be suspended (Grub Screws). In combination with bolted-on channels, the support brackets offer a wide range of possibilities for cantilever arrangements. In addition, the load capacity of crossbars can be increased by fixing them onto Support Brackets.

Support Bracket WK 100-200

2 Variants

Sikla Support Brackets may be used for wall, floor and overhead pipe installation. Depending on the site, pipes may lie on the support bracket (U bolt), be arranged in vertical position or be suspended (grub screws). In combination with bolted-on channels, the support brackets offer a wide range of possibilities for cantilever arrangements. In addition, the load capacity of cross-bars can be increased by fixing them onto Support Brackets.

Support U-UB F 80

1 Variant

Insulation and surface protection pad to be used on demand when a pipes’ expansion and contraction occurs directly on the F80 section.

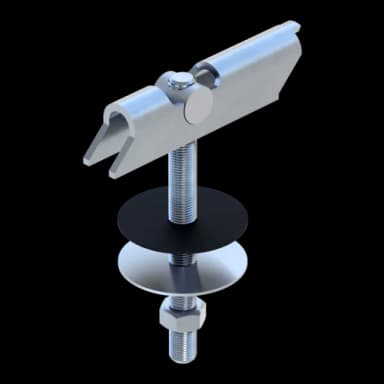

Toggle Stud KD

1 Variant

For fixing pipes up to a nominal diameter of NB50 directly to ceilings made of trapezoidal corrugated sheet according to VdS/FM standards or as single point mounting solution. In cases where VdS or FM regulations are not applicable or in cases of ventilation systems, larger loads may be fixed via crossbars and by an appropriate number of toggle studs. By turning the threaded rod, it is possible to make height adjustments. This threaded rod is secured and cannot be unscrewed completely. The Hypalon washer is weather-resistant and thus a crucial safety factor when sealing the mounting bore.

U Bolt Fastening UB F HCP

3 Variants

U Bolt Fastening to connect standard U-Bolts required for pipework to the supporting Beam Sections, Cantilever Brackets and Beam Brackets F80 or F100.

U Bolt RUB DIN 3570A HCP

10 Variants

For pipeline systems in industrial and residential buildings and Sprinkler installations according to VdS and FM standards. For horizontal and vertical pipelines, the U-Bolts are applied as Fixed Points and as Guiding Supports.

U Clamp RUC

2 Variants

For mounting pipes directly on a support, especially suitable as a replacement for U Bolts in connection with channels or cantilever brackets. When using T Bolts, their washer can be used in between the channel and the U Clamp. Dimensions and cross-sections are in keeping with the VdS standard.

U-Holder SB 41

1 Variant

Clamping element for bi-lateral attachment of crossbars to steel beams, independent from the channel's opening.

U-Holder SB F 80 HCP

4 Variants

Pre-assembled component to clamp Beam Section F80, to the flange side of traditional steel sections.

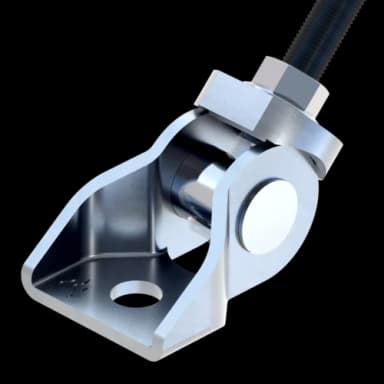

Universal Joint UG

2 Variants

Universal connection for attachment to non-horizontal components. May be fixed directly to building surfaces, Beam Clamps, channels, etc. Typical uses would include easy on-site manufacture of various tie rod assemblies to support brackets, or reinforcement struts for sliding and fixed point applications (UG FP types are specifically designed for assembly for pipe clamp wings for fixed point constructions). Infinitely variable angle adjustment. Length and height adjustment via rotation of the grub screw in the threaded pivot head. Securely retained threaded pivot head. Secure attachment of nut on the adapter plate.

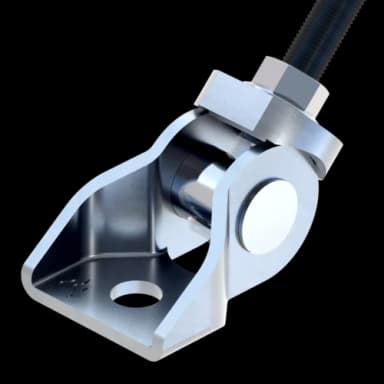

Universal Joint UG A4

1 Variant

Universal connection for attachment to non-horizontal components, allowing infinitely variable angle adjustment. May be fixed directly to the building surfaces, Beam Clamps, channels, etc. Typical uses would include easy on-site manufacture of various tie rod assemblies to support brackets, or reinforcement struts for sliding and fixed point applications: Infinitely variable angle adjustment. Length and height adjustment via rotation of the grub screw in the threaded pivot head. Pivot head caulked, prevents from falling out.

Webbing Plate KNO

1 Variant

Connecting element for framework structures of Sikla Channels MS 27.

Welding Adapter ASA F 80 HCP

1 Variant

Welding plate with square insert to receive siFramo section. May be implemented into the structural steel design in anticipation of siFramo-frames or used in situ as a connection element when clamping is not an option but hot works are permitted.

Welding Adapter ASA F100 HCP

2 Variants

Welding plate with square insert to receive siFramo section. May be implemented into the structural steel design in anticipation of siFramo-frames or used in situ as a connection element when clamping is not an option but hot works are permitted.

Welding Plate SPL F 80 HCP

1 Variant

Interface element to enable a welded connection of load chains, spring hangers etc. to Beam Section TP F. Our type 'SPL universal' enables a welded connection to primary steel with flange width up to 300 mm. At the same time it's possible to install type 'SPL universal' to Beam Section TP F if a larger installation surface is needed. The welding plate can be welded directly without previous treatment due to a corrosion-resistant weld-thru coating which is compatible with both the HDG surface of the siFramo section and the health and safety requirements of the welding process.

Welding Plate SPL UNI HCP

1 Variant

Interface element to enable a welded connection of load chains, spring hangers etc. to Beam Section TP F. Our type 'SPL universal' enables a welded connection to primary steel with flange width up to 300 mm. At the same time it's possible to install type 'SPL universal' to Beam Section TP F if a larger installation surface is needed. The welding plate can be welded directly without previous treatment due to a corrosion-resistant weld-thru coating which is compatible with both the HDG surface of the siFramo section and the health and safety requirements of the welding process.