STA F 100 - 80

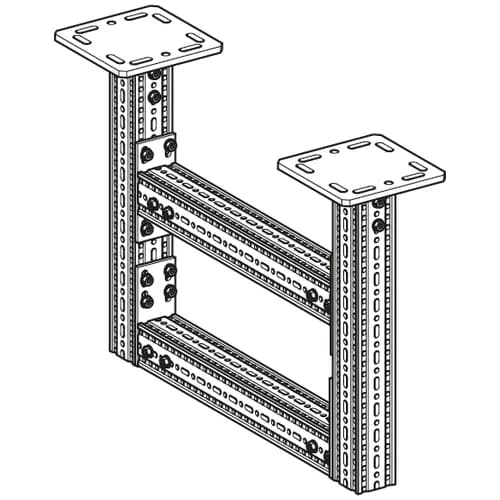

End Support STA F100-F 80 HCP

Group: A822

Part number 113337

End Support enables flexible design options in combination with brackets or profiles

Compatible with F 100 and F 100/160 profiles for a wide range of applications

Technical Data

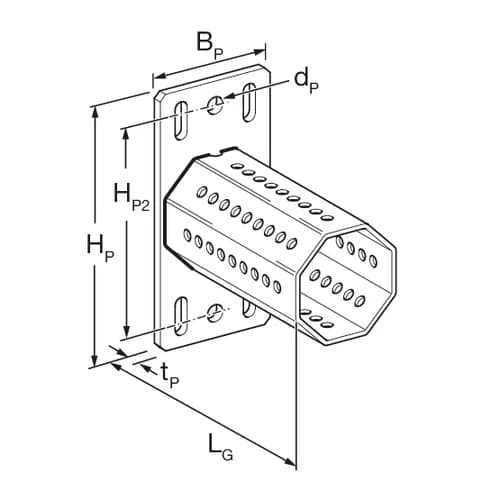

BP | 100 mm |

dP | 14 mm |

HP | 210 mm |

HP2 | 170 mm |

LG | 148 mm |

tP | 8 mm |

Technical specifications

Material base body | steel |

Surface | HCP |

Corossion class | C4 |

Also available with DUALSHIELD for high corrosion protection within C5H environments.

Certification

CE mark (Declaration of performance see downloads)

ETA-24/0471

Installation

Type STA F 100 and 100-80:

Depending on the situation, different options are recommended:

a) With 2x4 Self Forming Screws FLS when used to connect 2 Beam Sections.

b) With 4 Self Forming Screws FLS applied to the octagonal insert and 2 suitable wall anchors/fixings when connected to the building structure.

The Beam Section TP F 100/100 connected to the End Support STA F 100 has to be screwed with 4 Self Forming Screws FLS F. On each of the opposite sides 2 Self Forming Screws FLS F are necessary. Alternatively with two suitable wall anchors through holes “A” when fixed directly to building structure.

Configuration: Base plate welded to Octagon F 100 or F 80

Type STA F 100-100/160:

For the connection to Beam Section TP F 100 or TP F 100/160 (flange side 100) 4 Self Forming Screws FLS F are necessary.

The Beam Section TP F 100/160 connected to the End Support STA F 100 - 100/160 has to be screwed with 8 Self Forming Screws FLS F. On each of the broader sides 4 Self Forming Screws FLS F are necessary.

Configuration: Base plate welded to Octagon F 100/160

Documents

- siFramo - ETA-24/0471

PDF (2.15MB)